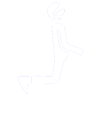

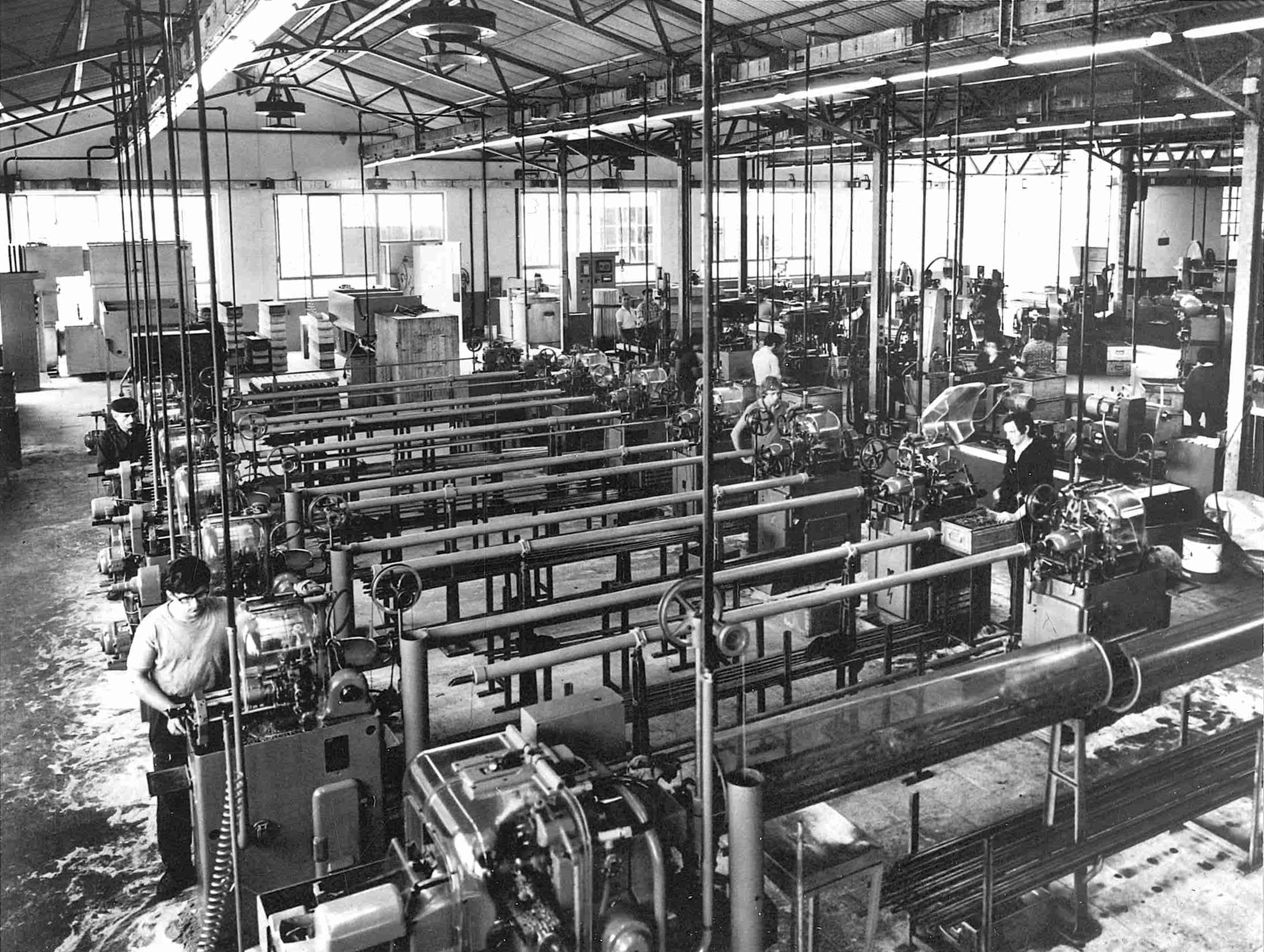

For over 15 years, Cober has been committed daily to respecting the environment through the choice of high quality raw materials and the use of cutting-edge machinery, whose constant updating allows us to always maintain high quality standards and respect for the environment. In addition, the choices made so far in the field of raw materials reduce the daily exposure to risks of our staff to almost zero.

The sustainability path concerns various production processes, including powder coating, solvent-free UV screen printing and molding of second-life plastic components. Furthermore, all our raw materials are subjected to severe tests for their toxicity.

Powder coating

20 years ago, Cober decided to install its own painting plant by choosing powder coating. This painting method has a positive impact on the environment, unlike liquid painting which is extremely polluting, and is also an improvement for the health of operators, exposing them to much lower risks, as they are no longer in contact with toxic and polluting materials. In addition to that, powder coating is more resistant to scratches than the liquid one, making the poles more resistant to time and use.

UV silkscreen printing

For 15 years now, Cober decided to use an innovative and environmentally friendly method for silkscreen printing its shafts. Silkscreen printing is a method of printing graphics for the decoration of the shafts. These graphics are screen-printed using solvent-free inks, eliminating any danger both for the environment and for the workers. In addition, the inks are catalysed through UV light, with an energy and therefore environmental advantage, as the energy consumed by UV lamps is drastically lower than that required in standard ovens to catalyse solvent-based inks.

100% recyclable aluminium

The selection of aluminium too follows Cober’s sustainable guidelines. For several years, in fact, Cober has been buying aluminium of European production only, because it has low greenhouse gas and CO2 emissions into the atmosphere; for Cober it is essential that all its choices are oriented to preserving the Planet. Both types of aluminium purchased have a percentage of recycled elements, ranging from 53% to 85%, and are both 100% recyclable.

Second life plastic grips

Cober presented the first second-life plastic ski grip in January 2020. This kicked off the Leaves Project, which aims to replace plastic components now molded with virgin plastic, with our own developed formula of second-life plastic. Our plastic molding department, in order to try to reuse waste in the best possible way, has studied, together with a specialised company, a way to re-insert part of our production waste into the production cycle, creating an internal circular economy. The waste material that cannot be reinserted into COBER’s production cycle is reintroduced into the production cycle of other companies.

CLIMA is the first second-life plastic grip developed by Cober; it was used on an alpine ski pole, and was then also introduced on some models of the summer 2021 collection. The grip, in second-life plastic, has an ergonomic shape, which facilitates the use with gloves of any thickness and size. The material developed for the grip is soft touch.

From waste to finished product – The process that led to the creation of the second life plastic grip, involved several phases, from the recovery of the plastic material from production waste , to the selection and washing of the material for the transformation into granules, up to product design and engineering. Finally, we came to the molding of the second-life plastic grip.

From an accurate series of tests, the material developed for this grip appears to have the same mechanical characteristics of the virgin material previously used.

Raw material testing

Raw materials are tested to verify their toxicity, therefore testifying their non-toxicity. We test our materials to guarantee our customers quality products that do not harm their health and that of the surrounding environment.